The question is: which characteristics are important when selecting a silica product for a chromatographic application? Here’s a rundown of key attributes and why each one may prove pivotal in your separation.

Before we begin, however, there is one principal aspect that is of paramount importance: batch-to-batch consistency. All of the parameters discussed below must be constantly evaluated and optimized by the manufacturer to ensure tight control over manufacturing - and maintain consistent quality and performance.

How to Choose a Silica-Based Stationary Phase Packing Material

Here are seven key traits to consider:

1. Particle shape

The shape of silica particles can have a significant impact on separation efficiency. Spherical particle shapes result in more homogenous packing characteristics than irregular shapes. Spherical silicas are more resolutive, and peaks are farther apart from each other. This allows flow rate to be increased, which can accelerate the speed of analysis and consume less solvent. The results are sharper peaks and the ability to isolate closely-eluting compounds from one another.

SiliCycle’s SiliaSphere PC, for instance, combine a perfectly spherical shape with a smooth surface free of cracks and cavities to ensure consistent packing material performance.

Irregular-shaped silica gels are also used in chromatography, typically for flash and low to medium-high pressure applications. Irregular silicas tend to be used in open column, gravity chromatography, and are an economical option. They are ideal for preparative chromatography and are used across scales – from laboratory to pilot to production.

SiliCycle’s irregular-shaped silica product, SiliaFlash, is available for the two most common sized 60 Å gels: 40-63 μm and 60-200 μm. It is produced in two different grades – Standard and Superior. The Standard grade ensures fines have been removed to maintain narrow particle size distributions, while the Superior grade requires an additional step to reduce metal content and further tighten the particle size distribution.

Generally, there are distinct advantages to using spherical silica over irregular gels. One SiliCycle study demonstrated that not only does spherical silica show better performance, but it also allows for increases in flash cartridge loading without adversely affecting the performance of the separation.

2. Particle size

Matching particle size to the targeted application is essential, with different particle sizes used for different analytes. While the most common silica particle size used in chromatography is 40-63 µm, we encourage you to contact us to discuss your specific application if you have any questions or concerns.

Here are some general guidelines for selecting particle size:

| Generated Pressure (GP) or Selectivity (α) | ||||||

| ▼ | ▼ | ▼ | ▼ | |||

| GP ~950 psi (65 bar) α < 1.2 (very difficult separation) |

GP ~220 psi (15 bar) 1.2 < α < 1.5 (difficult separation) |

GP ~73 psi (5 bar) 1.5 < α < 2.0 (possible separation) |

GP ~29 psi (2 bar) α > 2.0 (easy separation) |

|||

| ▼ | ▼ | ▼ | ▼ | |||

| From 0 to 30 μm | From 15 to 40 μm | From 40 to 100 μm | From 40 to 1,000 μm | |||

3. Particle size distribution

Silica gel particle size, discussed above, has an obvious impact on performance – and so does particle size distribution (PSD).

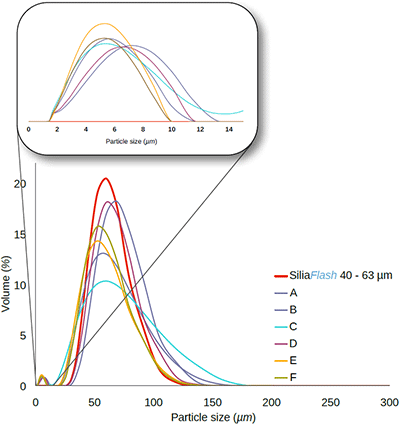

PSD indicates the proportion of different particle sizes present in a sample. It is typically shown as a curve, with higher peaks (and narrower curves) indicating a tighter distribution.

In the chart (right), SiliaFlash – noted as a red line – has the tightest particle size distribution, meaning the range of particle sizes is very narrow and the particles are more uniform in size.

A narrower PSD allows for a more homogenous packing, and thus more concentrated fractions. It also reduces solvent consumption, yielding more cost-efficient processes.

How does particle size distribution impact column performance?

With a broad PSD, the packing is uneven. Some parts are composed of only large particles where the solvent will flow fast and meet little resistance. Where the packing is composed of small particles, the solvent will flow slowly and meet greater resistance. When this occurs, the solvent will take the path of least resistance through the column. These preferential paths create uneven flow and impact the separation, since compounds will have different retention times depending on their flow path. As they exit the column, the compounds will give broad and poorly separated peaks.

When discussing a silica’s PSD, one key challenge emerges with the presence of “fines” – or small particles under 10 microns. In chromatography, fine particles increase backpressure and can result in clogging. Fines can also pass through filters and contaminate final product.

For example, a silica product sold as a 40-63 µm gel will have a portion of particles larger than 63 µm as well as a proportion of particles with a size under 40 µm (including fines). The width of the distribution specifies what proportion of particles will fall outside the product’s range of 40-63 µm.

While virtually all silica gel manufacturers sell a 40-63 µm gel, they are by no means equal. Most products have a mean of 80% particles within the nominal range (in this case, 40-63 µm), while our SiliaFlash gels have a mean of 90% - delivering fewer fines. This is an important distinction, since the presence of fines can lead to higher backpressure, clogging and contamination. The absence of fines provides a more consistent, stable, and reproducible chromatography bed, resulting in a faster and more even flow rate for better separation.

Particle size distribution is determined by either dynamic light scattering (DLS) measurements or sieving analysis.

4. Pore size

As with particle size, pore size selection is highly dependent on both the target analyte and the type of chromatography being performed.

Bigger pore sizes (larger pore diameters) tend to lead to lower surface availability, while smaller pore sizes offer a higher surface area. A larger surface area allows for greater loading capacity and results in more contact or interaction with the analyte. This improves separation power and is more economical in terms of solvent usage.

Pore size is measured in angstroms (Å) and is classified as micropores, mesopores or macropores.

| Pore Type | Pore Diameter |

|---|---|

| Micropore | radius of < 10 Å |

| Mesopore | radius of 10-250 Å |

| Macropore | radius of > 250 Å |

As a general guideline, smaller molecules are ideally purified using smaller pore sizes while larger molecules use larger pore sizes. For example, pore sizes of 60-70 Å are used for organic molecules with molecular weights of less than 1,000 Daltons (pore sizes of 30-40 Å are used for smaller organic molecules of less than 400 Daltons). With large proteins such as polypeptides (greater than 10,000 Daltons) a pore size of about 500-1,000 Å is used.

The most common method of determining the surface area of silica is the use of the Brunauer, Emmett and Teller (BET) analysis. The Barrett-Joyner-Halenda method on the other hand is used to determine the pore diameter and pore volume.

5. Trace Metals

Of critical importance is to ensure that a silica product has very low trace metal content. This minimizes any issues from metal oxides that may act as Lewis acids, and prevents tailing of most polar compounds that can be caused by silica with a high metal content.

Silica gels are typically analyzed for metals using inductively-coupled plasma mass spectrometry (ICP-MS), which offers very low thresholds of detection. SiliCycle, for instance, analyzes for more than 45 different metals using ICP-MS to ensure high purity and extremely low (or undetectable) levels of trace metals.

| Product | F60 R10030B | P60 R12030B | Acid Washed* R10530B | G60 R10040B | GE60 R10140B | |

|---|---|---|---|---|---|---|

| Particle Size | 40 - 63 μm | 60 - 200 μm | ||||

| Pore Diameter | 60 Å | 60 Å | ||||

| Metal (mg/kg) | ||||||

| Aluminum | Al | > 200 | > 1,000 | > 70 | > 350 | > 900 |

| Antimony | Sb | > 0.2 | > 0.2 | |||

| Arsenic | Ar | > 1 | > 1 | |||

| Barium | Ba | > 40 | > 40 | > 5 | > 40 | |

| Beryllium | Be | > 0.1 | > 0.1 | |||

| Bismuth | Bi | > 1 | > 1 | |||

| Cadmium | Cd | > 0.01 | > 0.01 | |||

| Calcium | Ca | > 200 | > 500 | > 10 | > 250 | > 500 |

| Chromium | Cr | > 1 | > 1 | |||

| Cobalt | Co | > 0.1 | > 0.1 | |||

| Copper | Cu | > 1 | > 1 | |||

| Iron | Fe | > 75 | > 350 | > 10 | > 75 | > 350 |

| Lead | Pb | > 1 | > 1 | |||

| Lithium | Li | > 0.1 | > 0.1 | |||

| Magnesium | Mg | > 150 | > 250 | > 10 | > 100 | > 150 |

| Manganese | Mn | > 1 | > 2 | > 1 | > 1 | |

| Molybdenum | Mo | > 0.1 | > 0.1 | |||

| Nickel | Ni | > 1 | > 1 | |||

| Potassium | K | > 500 | > 30 | > 2 | > 750 | > 30 |

| Rubidium | Rb | > 0.2 | > 0.2 | |||

| Selenium | Se | > 1 | > 1 | |||

| Silver | Ag | > 0.1 | > 0.1 | |||

| Sodium | Na | > 150 | > 1,500 | > 15 | > 150 | > 1,500 |

| Strontium | Sr | > 4 | > 15 | > 1 | > 4 | > 15 |

| Tellurium | Te | > 0.1 | > 0.1 | |||

| Thallium | Tl | > 0.1 | > 0.1 | |||

| Tin | Sn | > 0.4 | > 0.4 | > 0.2 | > 0.4 | |

| Titanium | Ti | > 200 | > 250 | > 90 | > 250 | |

| Uranium | U | > 0.1 | > 0.1 | |||

| Vanadium | V | > 1 | > 1 | |||

| Zinc | Zn | > 1 | > 1 | |||

* Acid washed SiliaFlash 40 - 63 μm, 60 Å silica gel for extra purity (R10530B). This product has been developed to ensure a pH-controlled media with even lower levels of trace metal contaminants and maximal purity.

6. Water content

The amount of water on the silica’s surface affects its selectivity, and thus its chromatographic performance. Anhydrous silica gels are exceptionally polar, while a wetted gel is considerably less polar. Silica manufacturers typically target water content levels of 2-9%, though this can introduce excessive variability (SiliCycle’s SiliaFlash has a much more controlled water content of 4 to 6%, and we can also adjust water levels upon request).

7. pH

The pH of silica can also have an impact on separations. It can increase the retention of some ionizable compounds, but some products can become hydrolyzed or rearranged when in contact with an acidic silica.

While it is common for silica gels to have a pH in the 6.0-7.0 range, our silica is pH-adjusted between 6.5 and 7.5 to ensure it is inert and can be safely used to separate a wide range of products. This is critically important with pH sensitive compounds, which require a neutral pH for separation.

pH tests involve suspending the silica gel in pure water (5 % w/w).

At SiliCycle, we work closely with bio/pharma companies and contract manufacturing organizations to determine the right product for a project. We also offer R&D services for special projects, testing and customized functionalized silicas.

0 Comments